The Role of Spiral Conveyors

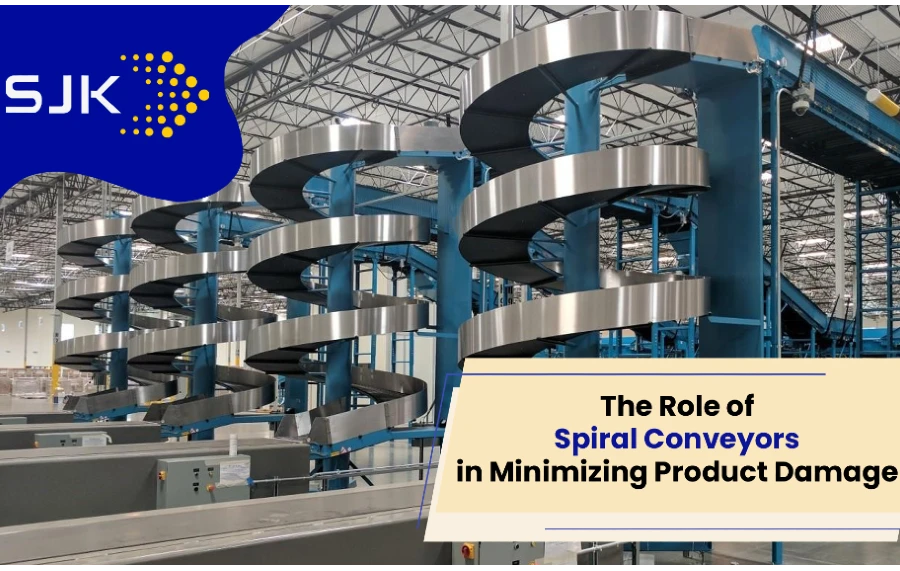

Spiral conveyors play a pivotal role in minimizing product damage, and revolutionizing the way goods are transported within various industries. These conveyors, known for their space-saving design and gentle handling, have become indispensable in warehouses, distribution centers, and manufacturing facilities worldwide.

At the core of their functionality lies the innovative spiral design. Unlike traditional conveyors that operate on a linear path, spiral conveyors utilize a helical track that allows products to flow continuously in a downward or upward spiral motion. This unique design significantly reduces the need for multiple conveyors or manual handling, thereby streamlining the workflow and optimizing space utilization within a facility.

One of the primary advantages of spiral conveyors is their ability to minimize product damage. The gentle, controlled descent or ascent along the spiral path ensures that items move smoothly without abrupt stops or impacts, preventing jostling or collisions that often lead to damage. Whether handling delicate items like glassware, electronics, or perishable goods, these conveyors provide a cushioned journey, safeguarding the integrity of the products throughout the transportation process.

Moreover, these conveyors offer versatility in handling various product types, sizes, and weights. With customizable configurations and adjustable speeds, they accommodate diverse materials, from small packages to bulkier items, without compromising on efficiency or safety. This adaptability makes them a preferred choice across industries dealing with a wide array of products.

Beyond their role in damage reduction, spiral conveyors contribute significantly to operational efficiency. Their compact footprint and vertical layout optimize floor space, allowing for better utilization of the facility's real estate. This compactness also translates into cost savings by minimizing the need for additional infrastructure and manual labor, ultimately boosting productivity and throughput.

Another critical aspect of these conveyors is their contribution to maintaining product integrity and compliance with industry regulations. In industries where maintaining the pristine condition of goods is paramount, such as food and pharmaceuticals, these conveyors offer a hygienic and controlled environment, meeting stringent quality and safety standards.

Furthermore, the seamless integration of spiral conveyors with existing material handling systems enhances overall logistics and distribution processes. They can be easily incorporated into automated systems, facilitating a smooth flow of goods from one processing stage to another, thereby reducing bottlenecks and ensuring continuous operations.

At SJK, we are committed to delivering top-notch material handling solutions that redefine efficiency and reliability. Our spiral conveyors are meticulously crafted to cater to diverse industry needs, offering a broad spectrum of sizes and configurations. With precision engineering and high-grade gravity rollers, our systems ensure seamless product transportation while minimizing energy consumption. Our dedication to warehouse automation in Coimbatore underscores our mission to empower businesses with cutting-edge solutions, optimizing their supply chains and operational capabilities. Experience the difference with SJK's high-quality and bespoke conveyor systems, where innovation meets excellence in material handling technology.